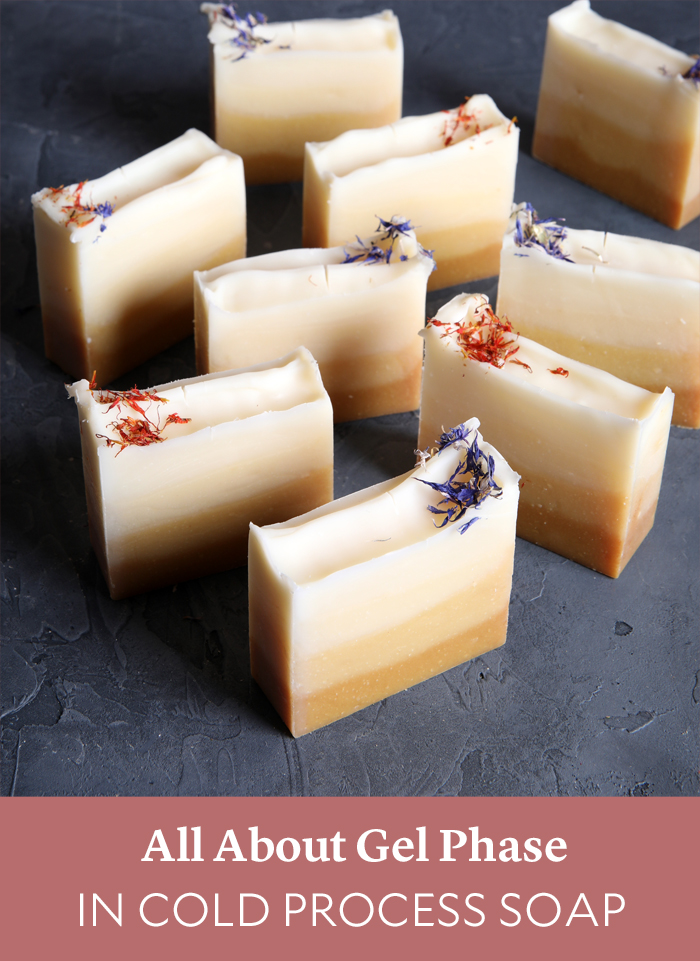

Has your cold process soap ever looked gelatinous after a few hours in the mold? It’s likely going through gel phase. That’s a part of the saponification process where the soap gets hot – up to 180°F. It doesn’t affect the quality of the final bars, but it does affect the way they look.

You can choose whether to force gel phase based on your recipe and personal preference.

This

This

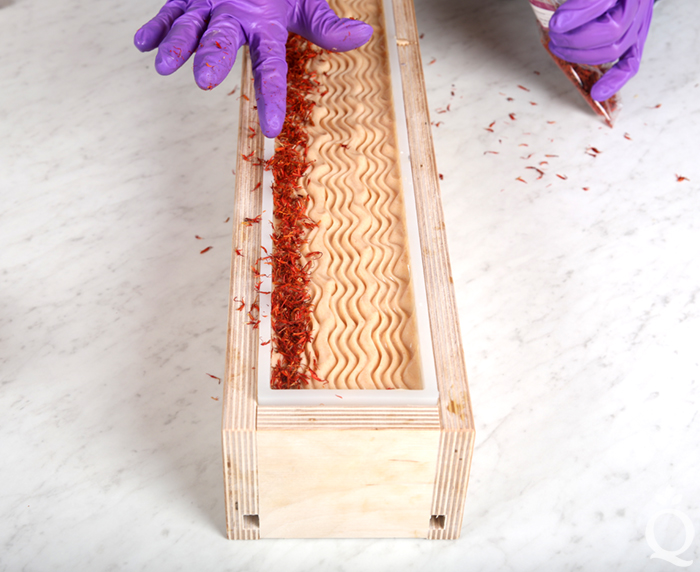

In this example, the glycerin dew is concentrated around the outside of the bars.

In this example, the glycerin dew is concentrated around the outside of the bars.  Glycerin dew has formed around the corners of this bar.

Glycerin dew has formed around the corners of this bar.