If you want to customize soap down to the last ingredient, cold process is a great option. You get to choose the oils, colorants, scents, and more. Once you find your perfect recipe you can start getting creative with the designs.

Cold process soap is made by combining oils and sodium hydroxide lye. That causes a chemical reaction called saponification. Melt and pour soap has already gone through that process – learn more about working with it here.

Below you’ll find cold process terms, safety tips, and a list of the equipment you need to get started.

COMMONLY-USED TERMS

Trace: This is the point when the oils and lye water are emulsified. At thin trace, there will be no streaks of oil and the soap will be the consistency of thin cake batter. As the soap sits, it will continue to thicken to medium and thick trace. This video has more information and examples of each stage.

Gel phase: During gel phase, soap gets as hot as 180°F and develops a gelatinous appearance. Learn more in the Jazzed About Gel Phase post. Gelled soap has a brighter color and a slightly shiny appearance. It can also be unmolded more quickly. Some makers force their soap through gel phase with blankets and heating pads. However, gel phase isn’t required – it’s personal preference. It only affects the look of the bars, not the quality. Ungelled soap has a more matte appearance. You can prevent gel phase by putting soap in the freezer for 24 hours. Learn how to force it or prevent it in the When to Insulate Handmade Soap post.

Curing: Technically, cold process soap is safe to use after a few days. However, we recommend letting the soap cure for 4-6 weeks in a cool, dry place with good airflow. Excess water will evaporate, which creates harder and milder bars that last longer in the shower. It’s definitely worth the wait.

Lye Calculator: This tool makes formulating cold process recipes easy. All you have to do is enter the oil weight or percentage and the Lye Calculator will give you the lye and liquid amount you need for your recipe. It also calculates the superfat level. Learn how to use the Lye Calculator here.

Soda ash: This creates an uneven, white, ashy film on soap. It forms when unsaponified lye reacts with naturally-occurring carbon dioxide in the air. It doesn’t affect the quality and the soap is safe to use. However, it can obscure more intricate designs or make the bars feel crumbly. You can prevent it with a few tricks, including a 10% water discount and gel phase. Learn more in the Explaining and Preventing Soda Ash post.

LYE SAFETY

Lye is a highly corrosive product. It’s safe to use as long as it’s handled properly. Before getting started, make sure to watch this video or read this post about lye safety. Make sure there are no kids, pets, or other distractions in the room when you’re making soap and always do so in a well-ventilated area. You’ll need the following items to work with lye.

Gloves: Rubber dish gloves that go almost to the elbow work great, but they can be bulky. Thinner nitrile or latex gloves provide protection without the bulk. Whatever you choose, they should be paired with long sleeves.

Goggles: Alkali burns are extremely dangerous for your eyes. Your safety goggles should protect them from all sides, so regular glasses aren’t sufficient protection. If you wear glasses, make sure to get goggles that fit over them.

Long sleeves, pants, and close-toed shoes: Protect yourself from unexpected splashes by covering any exposed skin.

Face mask: This is an optional step. If you’re sensitive to lye fumes or if you’re making large batches, you can wear a dust mask.

EQUIPMENT

Any equipment used for soapmaking should be exclusive – don’t use it for food. Lye and fragrance can get stuck in cracks, even with thorough washing. We also recommend hand washing instead of using the dishwasher. Learn more about how to clean soapmaking tools in this post.

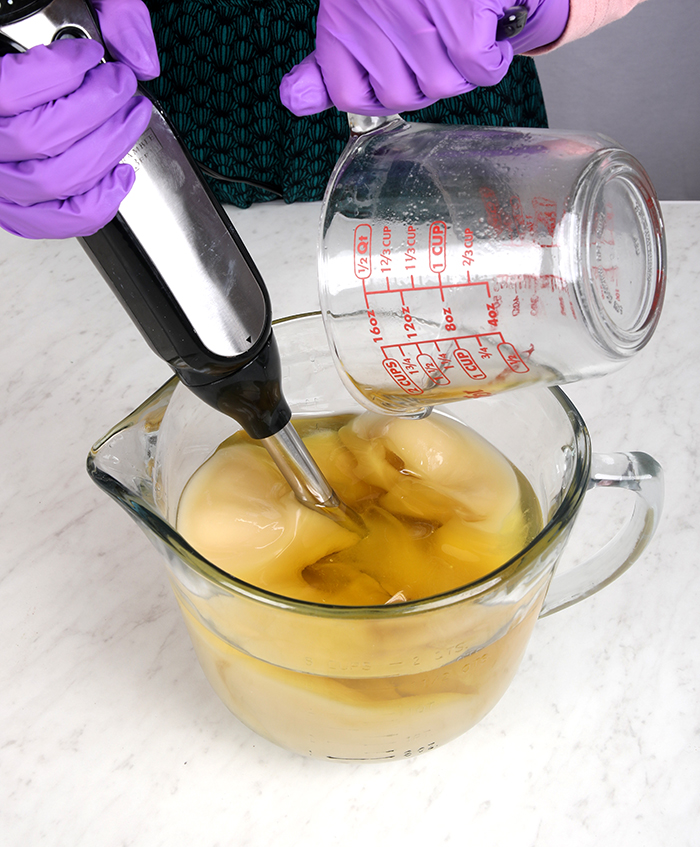

Containers: We recommend heat-safe glass, plastic, or stainless steel bowls. Don’t use aluminum – it can react with the lye and create toxic fumes.

Stick/immersion blender: Using a whisk or stand mixer can take hours. Stick blenders emulsify the soap in just a minute or two, so it’s worth the investment.

Silicone spatulas and spoons: Use these to scrape every last bit of soap out of your container and into the mold. They’re also great for smoothing the top or creating texture.

Scale: For accuracy, all of our soap recipes are measured by weight instead of volume. This is a good $20 starter scale.

Soap molds: There are plenty of options to choose from. This post can help you decide which one is right for you.

- Silicone molds: These molds are easy to use, unmold, and clean. They’re a great option for beginner and advanced crafters.

- Wood molds: These are great for large batches and they make it easy to force gel phase. They need to be lined with freezer paper or a silicone liner.

- Plastic molds: You can use these for cold process, but they do require a few extra steps. We recommend a recipe with lots of hard oils and sodium lactate to help the bars come out cleanly and quickly. Get more tips here.

Beginner Recipes

Simple and Gentle Soap

Simple Castile Soap

Menthol Crystal Soap

Simple Coffee Soap

Swirled Rose Soap

Intermediate Recipes

Chopped Embed Soap

Crescent Moon Soap

Swirled Orchid Soap

Pink Salt and Gold Soap

Moonstone Soap

Advanced Recipes

Safflower and Ginger Soap

Siren Soap

Birchwood Oud Soap

Cactus Flower Soap

Chocolate Peppermint Soap Cupcakes

More Cold Process Resources

Common Soapmaking Oils

Formulating Cold Process Recipes

How to Color Handmade Soap

Back to Basics Series Roundup

Using the Bramble Berry Fragrance Calculator

This post was updated in January 2019.

hi

I’m going to start soap making. I have doubt about the kind of sodium hydroxide. I don’t know if it is possible to use NaOH that is not from a good brand(like Merck).I dont know if it must be high grade or no.

I’ve bought one that wasn’t expensive.

As long as it is actual sodium hydroxide the brand doesn’t necessarily matter. You will want to check the purity though as that can affect how well the soap you make will harden. Our recipes call for a 97% pure lye so if yours is only 90% you will need to add 7% more lye in order to get the same effect we got in our recipe.

Hi

I’ve just made a batch of soap. However, after weighing all the ingredients out I realised I had my scales set on fluid ounces instead of ounces. Will the soap be safe to use?

That depends on the specific recipe and how much ended up being used. As long as the soap isn’t lye heavy it would be safe.

Find out how to check for and troubleshoot lye heavy soap here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

Hello, I am starting making soaps and I have some questions. I do not want to use palm oil in my soaps, I made a recipe that is 40% olive oil , 30% coconut oil, 15% sunflower oil, 5% castor oil and 10% shea butter. I would like to put almond oil but I am not sure if it will be too much and the effects in the soap. Is that a good recipe to clean, give the soap lather and be gentle to skin without being oily or stick?

also…

I made a batch with 45% olive oil, 30% coconut oil, 5% castor oil, 5% sweet almond, 15% sunflower oil but it is soft even after 5 days in the mold… Is that a good recipe? thanks a lot

Hi Soapqueens,

Can I add titanium dioxide and desiccated coconut to this batch to make it a white coconut soap? I’d also like to up the coconut oil %.

This is my first CP attempt so I don’t want to mess it up.

Sure you can definitely do that! If you use too much Coconut Oil though it can be a little drying for the skin.

Hi team,

I was actually trying to leave a comment under the Castille Soap tutorial but I cannot find the ‘leave a comment’ section.

I have a very daft question. I want to make the castille soap and leave it in the mold for a few days to harden. However, I don’t really have molds to spare. Prepare yourself for a daft question. Can I line a study cardboard box with baking paper and use that as a mold? If i make sure there’s no gaps/leaks and the cardboard is sturdy enough to hold the soap?

Thanks in advance!

Claire

Yes, if your cardboard is sturdy enough without any gaps or leaks you can use that to make your castile soap. I would recommend lining it with freezer paper first.

This post on How to Line Any Mold may help with that: https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/how-to-line-any-mold/

Awesome! Thanks so much.

Hi Soapqueens,

I am just starting out and I have never made cold process before. I’m so excited to try. However, I want to product a palm oil free product. Are recipes without palm oil supposed to be for the more advanced soap maker?

Many thanks,

Claire

Palm free soap recipes can be a bit tricker but they don’t necessarily have to be. If you’re just getting started I think one of the simplest palm-free recipes would be our Simple Castile Cold Process Soap which is 100% olive oil. Just keep in mind it can take some patience waiting for it to harden.

Simple Castile Cold Process Soap Tutorial: https://www.soapqueen.com/bath-and-body-tutorials/castile-cold-process-soap-tutorial/

Here are some other more simple palm-free recipes you may like:

https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/buttermilk-bastille-baby-bar-on-soap-queen-tv/

https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/a-palm-free-in-the-pot-swirl/

I’m a newbe but successful so far. my question ie how long to cure pure olive oil using cold process I’ve heard 4-6 weeks now hearing 6 months. I live at 7200 ft in Wyoming does that matter? thanks Jane Hammond

Pure Olive Oil soaps tend to take longer to cure to a really hard soap so some people leave them for 6 months to a year. But you are more than welcome to use them after 4-6 weeks, they just might be a bit soft.

Hi!

I have made cold process soap a few times before, and want to properly get into it. I want to make a relatively hard bar with lots of lather that is still gentle on skin, to be used as an all-purpose type soap (washing clothes, doing dishes, etc.) I imagine it to be a bit like Sunlight soap (although I’m not sure you have that in America!). However, I don’t want to use palm oil. I have done some research and here is the recipe I have come up with:

24% coconut oil

44% olive oil

4% castor oil

8% shea butter

8% cocoa butter

12% canola oil.

Does that match my description – will it turn out at least somewhat like the bar I want? And Do you have any other advice on my formula?

Thanks heaps!

That recipe sounds perfect, the castor will definitely help the lather and you have enough hard oils and butters in there to make a pretty long lasting, harder bar.

I have been soaping for a couple years. Goat milk soap is new to me though. I made some today, but the lye milk mix only got to 85 ° F. I know the cooler temps make it harder for lye to dissolve so I stirred stirred stirred. The oils (half coconut half olive) were 91 °F when I combined them. Everything traced fine and looked nice. However!!! I noticed a few fine grains in the container as I was washing up. I’m worried it’s definitly lye! Can I save this batch? What do I do? I’m sorry if this was asked before. Thank you! It looks so beautiful….

I can see some grains in the soap as it’s hardened….. definitely lye. Is it really trash? 800 g of oil, 310 g milk, 121 g of lye.

If soaping cooler those could be Palm Stearic flakes (from parts of the Palm Oil cooling and hardening), not lye flakes. I would weight a couple weeks then test those spots for lye heaviness. If they are not lye heavy your soap is safe to use.

Troubleshooting (and testing for) Lye Heavy Soap:https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

If the soap *is* lye heavy it still isn’t trash. You can turn the soap into laundry soap.

DIY Laundry Soap: https://www.soapqueen.com/bath-and-body-tutorials/home-crafts/three-diy-laundry-soap-recipes/

Hi! Thanks for the reply. I didn’t use palm oil. I only used coconut and olive oil. I guess I won’t trash it and just wait to test it. It’s definitely lye grains. I didn’t use flakes. Still savable?

If it is undissolved lye flakes those spots of soap can be irritating to the skin for sure. You may want to turn it into laundry soap to be safe.

Hello! I was just wondering, if we don’t cure the soap for the required time. (I’m letting it sit for a week), is it still safe to use?

Hi Joanne!

Most of the soap making process happens within the first 48 hours. That means after 3-4 days, your soap is ready to use!

We recommend letting it cure for 4-6 weeks because it creates a milder bar that lasts longer in the shower. However, you can definitely use your bars earlier. 🙂

-Kelsey with Bramble Berry

Hi,

I made a soap 2 weeks back. I tried it on 15 th day just to wash my hands. It lathers but looks slimy and my hands feel sticky after washing. I used 4% castor oil and 2% Neemseed oil oil in my recipe.

Will it be alright once cured for 6 weeks.?

It will definitely feel a bit different after the full curing time as the soap tends to harden and feel less slimy as it sits. The longer it sits the less water in the recipe which will stop it from feeling that way.

Hi,

I waited 6 weeks and tried my soap. It’s awesome. No slimy feel and it’s hard. Good moisturizing lather… I love it. Thanks team for your support.

I love your website. I have watched a lot of your videos and have perfected my own soaps. I especially love the safety videos that many websites are lacking including mine but I did embed your video on my site.

That is ok right?

Hi Brenda!

I’m so glad you like the website! Also, that is perfectly fine as long as the video links back to us or you mention us on your site. Thank you so much for sharing the videos. 🙂

-Kelsey with Bramble Berry

Hello again …

i tried making of this soap and i got not bad result but i want you to guide me how to :

1- How to control the PH of the soap ?

note my soap PH is 9.5-10.5 that PH including glycerol into the soap bar

2-after making the soap bar i fell that the soap bar still oily what ever the PH is over 9.5 so what was that?

i know that there is a glycerol exist into the bar which has 14 PH so if you would know how to separate it or how to control the PH.

thank you for your efforts 🙂

Hello!

The ideal pH for your soap is 9-11. Within the first few days of making your soap, it will have a different pH, but should mellow out.

Do you mind if I ask what’s in your recipe?

-Kelsey with Bramble Berry

sure of course ….

but that recipe just for trying ……

and i am using a cheap oils cause i do not want to lose a lot of materials.

Recipe 1:

125g Sunflower oil

125g Soya oil

33g Na OH

81g dis. water

64g starch powder (as the one we use to cooking)

4g Na Cl

2g odor

2g color

————————

Recipe 2 :

75g Sunflower oil

75g Soya oil

23g dis. water

9g Na Oh

1g Na Cl

—————————-

both seems pretty oily i do not know why ……?

Hello!

I ran your recipe through the Lye Calculator and your lye and water amounts are just fine.

I’m not familiar with some of the ingredients, like Na Cl, but I have an idea about your soap! Because your soap uses mostly soft oils, it may just need longer to cure. Soft oil recipes typically take at least two months to harden and cure, so I think letting them sit out in a cool, dark place may take away some of the oiliness. I’ll include a link that explains more!

-Kelsey with Bramble Berry

Lye Calculator: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

Olive Oil + Castile Soap Tutorial: http://www.soapqueen.com/bramble-berry-news/olive-oil/

Thank you …!

You’re welcome! 🙂

-Kelsey with Bramble Berry

hi please it’s urgent.

i really want a recipe to make soap using only sunflower,corn and olive oil. if 2 out of these 3 oils it’s also okay. ‘

and i have a question can the soap have a higher percantage of sunflower or corn oil rather than olive oil?

thank u in advance

Hi Bushra!

You can use olive oil at 100% in your recipe. You can also use sunflower oil at 100% in your recipes, but it is typically used at 20% or less. As for corn oil, I’m not sure! We’ve never used that product before.

You may want to make a soap that’s mostly olive oil with corn and sunflower oil at 20% or less. Keep in mind because you’re using all soft oils, your recipe will be very soft and take longer to unmold and cure.

To speed this process up, you can use 1 tsp. of sodium lactate per pound of oils to your cooled lye water. I’ll include a post about that below. 🙂

-Kelsey with Bramble Berry

Sunday Night Spotlight: Sodium Lactate: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

Free Beginner’s Guide to Soapmaking: Common Soapmaking Oils: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/free-beginners-guide-to-soapmaking-common-soapmaking-oils/

I am gathering my supplies for my first time soap making – and I would love to have a similar giant glass mixing/pouring handled container like yours pictured! Do you know where I might be able to find one similar to yours?

Thank you so much

Hi Amber!

That’s so exciting! We sell several glass containers you may like. We use them frequently in our soap lab and they last forever. 🙂

Happy soaping!

-Kelsey with Bramble Berry

2 Quart Glass Mixing Bowl: https://www.brambleberry.com/2-Quart-Glass-Mixing-Bowl-P5789.aspx

5 Quart Glass Mixing Bowl With Lid: https://www.brambleberry.com/5-Quart-Glass-Mixing-Bowl-with-Lid-P5606.aspx

nice work but i have a question here…..

i want to use potassium hydroxide instead of sodium hydroxide because i can not get sodium hydroxide.

what would be the difference for the result soap?

and about the recipe ……dose the concentration and the percent of potassium hydroxide is the same as sodium hydroxide?

thank you

Hello!

Potassium hydroxide is used for liquid soapmaking. When adding to bar soaps, it creates a liquidy oily mess, so I definitely wouldn’t use it in your cold process recipes.

You may search online to see if anywhere near you sells sodium hydroxide. We also sell it at brambleberry.com. 🙂

-Kelsey with Bramble Berry

Sodium hydroxide lye: https://www.brambleberry.com/Sodium-Hydroxide-Lye-2-lbs-P3037.aspx

How to Handle Potassium Hydroxide: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/potassium-hydroxide-safety/

Just ordered a ton of supplies and I’m ready to really get into soaping. I made five batches a few months back and feel I have the hang of it now. One thing I had to learn was to add a little extra FO’s or Eo’s in my soap recipes. Mine smelled ok when unmolding them, but when using them, there was very little scent to them. I do like my hands to smell nice after washing them 😀 Then I learned that those amounts listed were a “recommended” amount and almost everyone I talked to used more. I was using under so going to try more next batch! Can’t wait to see how that works.

Thank you for all your helpful videos! I’ve watched them all.

Carrie

Hi Carrie!

I’m so glad you’re having fun soaping! It’s definitely an addictive hobby. 🙂

You can add more fragrance or essential oil if you like. Keep in mind that some essential oils or fragrance oils may cause irritation if too much is used. The product description on brambleberry.com and our Fragrance Calculator is a great way to learn more about suggested usage rates!

-Kelsey with Bramble Berry

Fragrance Calculator: https://www.brambleberry.com/Pages/Fragrance-Calculator.aspx

I tried to make a soap a few weeks ago with coffee on one side and fragance (spellbound woods) on the other. The recipe is from one of your books.

I noticed that the half with coffee is quite hard and the part with the fragance is soft like butter on room temperature.

The coffee was damp when added but no extra water was added to the recipe for compensation of adding dry matter. Can I assume the part with fragance is softer due to adding extra (flüid) oil?

Hi Annemieke!

How long ago did you make the soap? The coffee grounds may have absorbed some of the moisture in its half, while the side without them still has moisture that will evaporate while it cures. It typically takes 4-6 weeks for that bar to cure. 🙂

-Kelsey with Bramble Berry

Hi Kelsey,

Thanks for your reply. According to my notes, it was made just 3 weeks ago :), it cannot be used yet.

I try to learn as much of the process as possible. It is nice to compare the two parts of this soap, especially since these are made equal, but have a different finish.

With kind regards,

Annemieke

Hi Annemeike!

I would recommend giving it another couple of weeks. The side with no coffee grounds should set up more and get harder.

Also, it would be interesting to watch how those two sides cure! 🙂

-Kelsey with Bramble Berry

I wonder if it is safe to use the same silicone mold for MP and CP soap making. If so, how can I clean the mold?

Hi Claire!

You can absolutely use our silicone molds for both melt and pour and cold process. They’re very versatile!

To clean it out, we recommend spraying the mold liberally with 91 or 99% alcohol and letting it sit for about 15 minutes. Rub it out with a paper towel, then wash it with warm water and dish soap. 🙂

-Kelsey with Bramble Berry

Is cold process soap prepared with neem oil as one of the soap making oil safe to use for small kids/toddlers?

Another query,

Are these Essential oil safe to use as fragrance in cold process soap preparation for kid (3 year old)

ylang ylang

grape fruit

orange

Thanks

Hi Akila!

When used in the correct amounts, Neem Oil is safe for a wide variety of purposes and for small children. It should not be directly applied to the skin. The same applies to essential oils. If used in the correct rates, they will be perfectly safe 🙂 They should never be applied directly to the skin. If you have any more questions, let me know!

-Amanda with Bramble Berry

Hello, am wanting to try my hand at soap making..Have been looking at several different sites, recipes..etc..lots of reading, studying..whewww!…lol..one thing I have noticed on recipes is that total ingredient % s are not equaling 100%..I am confused by this..could you please explain. I am wanting to use a simple recipe of coconut oil, olive oil and coco butter, but would like to use coconut milk in place of water. Is this a workable idea? Thank you for any help and suggestions..

Hi Jacilynn!

That’s awesome that you have been doing your homework! There is a lot to learn when it comes to cold process :). Regarding the oils not adding up to 100%, could you tell me a little bit more about the recipe? The percentages of oils should add up to 100, and then the water and lye is calculated based on your oils :).

When making your first batch of cold process, I would recommend using water instead of using a different liquid, like coconut milk or goat milk. Working with milk can be very tricky, because when the lye is introduced to milk, the milk scorches. If you’d like to learn more about making soap with milk, you may find the blog post below helpful!

Goat Milk Soap Tutorial:

http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/goat-milk-soap-tutorial-on-soap-queen-tv/

Looking at your combination of oils, using more than 5% of cocoa butter can lead to a very hard bar of soap, that can be brittle, or may even crack. I would recommend taking a look at the two posts below. One goes more in depth regarding oils and their recommended usage rates, while the other has tips on how to formulate recipes. I hope this helps 🙂

Common Soap Making Oils: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/free-beginners-guide-to-soapmaking-common-soapmaking-oils/

Formulating Cold Process Recipes:

http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/formulating-cold-process-recipes/

I hope this helps, let me know if you have any more questions 🙂

-Amanda with Bramble Berry

I read somewhere that you shouldn’t use glass for soap making because the lye will etch it and compromise the integrity. But I see you use large pyrex measuring cups. Have you had issues with this or is it only an issue if you don’t use a heat safe glass?

I’m just getting ready to start my soap making journey and I’m still doing all my research and gathering my supplies. Thanks.

Hi Amber!

We have never had any problems using glass containers when making cold process soap. I would highly recommend Pyrex glass, we have found it to be very sturdy and reliable 🙂 You may find our Tool Kit for Beginner’s helpful!

Beginner’s Soaping Tool Kit:

https://www.brambleberry.com/Beginners-Soaping-Tool-Kit-P5859.aspx

If you have more questions, don’t hesitate to ask!

-Amanda with Bramble Berry

Lye does etch glass, but it takes a while. Lye and lye solutions should be stored in plastic, not glass.

I am working with kids and soap making. I need ideas for making molds with the kids. Several resources have suggested clay but not what type. There is limited time so it can not be too complicated. All suggestions for molding materials are appreciated.

Hi Jon!

If you’re interested in making molds, you may find our Flexy Fast Molding Putty a good options! It allows you to use any object to create a silicone mold. It does take about 24 hours for the putty to set up. I hope this helps!

-Amanda with Bramble Berry

Hi, i am new to soaping, I’ve only made 2 batches so far and loved it. I have a question, what is the shelf life for cold process soaps? How do i know when they expire and are not safe to use?

Hi Cristina!

Good question. The neat thing about soap is that it never really “goes bad.” The pH level of soap does not allow for mold or bacteria to grow. That being said, after a while the soap will start to dry out, become crumbly, and the fragrance and colors will fade. This usually starts to happen within 6 months or so, depending on how the soap is stored. I hope this helps!

-Amanda with Bramble Berry

Hi

Could you let me know if handmade soaps can be used for small kids (3 year old). Is it safe for kids too?

Do we need to take care to use any special ingredients/oils when preparing soaps for kids?

I prepared soap with following ingredient – shea butter, olive oil, coconut oil, palm oil.

Can this recipe be used for small kids?

Thanks

Akila

Hi Akila!

Handmade soap is perfectly safe for children as well as adults :). There are no ingredients that you absolutely have to use when making soap for children, but you may want to design your recipe to be very gentle and hydrating. One of my favorite recipes for young children (and for myself!) is the Baby Bastille Soap which uses Coconut Oil, Olive Oil and Buttermilk to create a very hydrating, gentle bar of soap.

Buttermilk Bastille Baby Bar:

http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/baby-soap-buttermilk-bastille-baby-bar/

I hope this helps 🙂

-Amanda with Bramble Berry

I got our book for Christmas and decided to make a soap today.

It was all going ok but I decided to double the dose to fit in my mould but I forgot to double the lay and water.

The soap looks beautiful but I don’t think it will works . What should I do to make it work?

Thanks

Hi Meka!

Oh no! I hate when that happens. Unfortunately, there is no real way to save the batch. Because there was not enough lye water, you basically have a lot of free floating oils that did not turn into soap. You may find this video helpful, it gives a helpful visual demonstration of the saponification process 🙂

Superfatting Soap: An Explanation:

http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/superfatting-soap-an-explanation-2/

You’re batch is basically a soap that has been superfatted an extreme amount, and there is no way to add more lye at this point. If you have any more questions, feel free to ask 🙂

-Amanda with Bramble Berry

Hi I have

Hi, I was wondering can a soap that’s been placed in the refrigerator overnight to prevent gel phase, go thru gel phase once it’s been taken out of the fridge? I think that happened to my soap also I noticed that it started to develop soda ash even though I spray alcohol on it.

Hi Marleny!

Good question! If your soap is going to go through gel phase, it will do so as it is setting up. After it has set, it will not go through gel phase. So if you left your soap in the fridge and it did not gel, it would not start going through gel phase after it has been removed.

It’s normal for soda ash to form even if your soap did not go through gel phase. Although spraying alcohol on the soap will help prevent soda ash, it’s possible for some to still develop. Soda ash depends on lots of different factors including the temperature of your oils and the amount of water in your recipe. For more information regarding soda ash, you may find this blog post helpful!

Explaining and Preventing Soda Ash:

http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/explaining-and-preventing-soda-ash/

I hope this helps 🙂

-Amanda with Bramble Berry

Thanks, I mistook the color change thinking it was starting to gel, I had never had that happened before so it seemed really strange.

Hi Marleny!

You’re so welcome :). If you ever have questions, we are happy to help!

-Amanda with Bramble Berry

Hi,

I made my 1st batch yesterday. The recipe is just simple 150 gr of coconut oil (29 C), 350 gr rice bran oil with 6% superfat (165 gr water, 67.5 gr lye). I mixed the lye solution and oil at around 118 F (for both solution).

Because I’m using the spinning whisk (whisk that will spin on itself manually when I push the handle down) not stick blender I though it would take sometimes to reach trace, but to my surprise it actually quite quick, maybe within 1-2 minutes. And I’m not spinning the whisk continually too, just in short burst mixed with manual stirring.

The trace was quite thick, like yogurt, so I put it in my container straight away (no FO or color or any addition) and insulate it with tea towel and put it aside. I check it from time to time and quite exited when I see it enter the gel stage in the middle. After 8-9 hours, I remove the insulation because the temperature had gone down to room temp.

Today I unmold bar. It looked ok from outside but when I cut it, I saw white streaks in u-shape towards the bottom, like it was following the flow of the soap when I pour inside the mold. It kinda like halo-effect actually. The cut bars are smooth and have the same consistency though, I’m quite sure that it’s not lye or oil pocket because it didn’t leak anything. Here’s the picture: http://s30.postimg.org/ljx3ynv29/Soap_1.jpg

Also, I deliberately left a bit of raw soap yesterday to mixed with around 20-30% sea salt and just a little splash of lavender FO (I did the addition by feel) just to see what’s the difference and checking if my Lavender FO is compatible for soap making or not. I put it inside an individual mold and just cover the top with tissue. No insulation.

After around 3 hours, I unmold the salt bar and cut it into 2 to see the inside. It was a bit soft and I saw some salt clump but otherwise it looked normal. The color is uniform which is good, no streaking. Tissue get wet when it touches the soap but I guess after curing it won’t be a problem.

Is the u-shape white streaks dangerous? This is for personal use so if it’s just a cosmetic problem, I am actually quite ok with it.

Do you know why this happened? I’m planning to make another batch of soap, so if I did something wrong, I would like to avoid it later.

Help and thank you in advance.

Hi Jun!

Thanks for all this great information, the picture was really helpful! The white streaks in the soap are fine, your soap should be perfectly safe to use :). My best guess is that effect is heat related. Next time I would try not insulating your soap and see if that helps! I’m guessing that the streaks are due to the gel phase.

I hope this helps 🙂

-Amanda with Bramble Berry

Thank you so much for the reply. It’s great that my 1st attempt does not end up bad :). I’m planning on making castile soap next, just trying to figure out where to get the olive oil first.

I heard that big brand like Bertolli was involve in the fake olive oil scandal a few year ago, that’s makes me sad and mad at the same time. Been buying that brand for a while for cooking, it was so expensive too.

Have they fixed the problem? It’s hard to find local olive oil here (Indonesia) and I can only find those big brand olive oil in supermarket. There’s people selling them online saying they imported the stuff and have certification, but I’ve been burned before buying things in the internet. So I guess I’m just being very cautious.

Hi Jun!

I totally understand your caution. I did not hear about the scandal regarding Bertolli, so I’m not sure if it has been resolved. We have found that certain brands from the tore tend to go bad quicker, even when they claim to be pure. When buying online I would just do as much research as possible. We do ship internationally, so there is that option as well 🙂

Olive Oil, Pure: https://www.brambleberry.com/Olive-Oil-Pure-P5246.aspx

I hope this helps, Happy Soaping!

-Amanda with Bramble Berry

I might just do that. I have cousin in America, I’ll order when they’re coming here to visit to cut the shipping cost :). I guess the castile soap project has to be postponed.

I was thinking about doing salt bar for my 2nd soap now. I saw you salt bar recipe here: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/pretty-in-pink-salty-cold-process/. I want to modify it a bit by using 100% coconut oil, honey for the extra moisturizing effect and earl grey tea in it. Can I ask is it okay to use honey in salt bar? I tried looking for salt bar recipe using sugar in it but I couldn’t find it so I was wondering if it’s not possible for a reason.

I added melted beeswax at light trace and it solidified! I got lumps in my soap. I used a natural beeswax which I shaved off. What can be done to avoid this in future?

Hi there!

Working with beeswax can be tricky for this exact reason! I recommend adding the beeswax into your liquid oils, and heat the mixture until the Beeswax has melted entirely.

Melting the Beeswax in the oils facilitates even distribution of heat for optimum melting. This oil wax mixture will be very hot, so be careful!you’ll need to keep your oils above 170 degrees and work quickly to prevent the mixture from clumping.

You may find these cold process recipes using beeswax helpful!

Busy Beeswax Soap: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/beeswax-spoon-plop/

Honey Beeswax Cold Process:http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/honey-beeswax-cold-process-tutorial/

I hope this helps!

-Amanda with Bramble Berry

Sorry if this has been asked, but does anyone include the amount of fragrance oil into their “total oils” calculation?

Hi Savony!

Good question! You do not need to include your fragrance oils into your total oil calculation. You will base the amount of fragrance oil on how much soap you are making. For example, we recommend .7 ounces of fragrance oil per pound of cold process, and .5 ounces fragrance oil per pound of melt and pour. For more info on how to calculate fragrance oil usage, you may find this blog post helpful!

Using Bramble Berry’s Fragrance Calculator:

http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/use-fragrance-calculator/

This post explains how to use out handy-dandy fragrance calculator, which you can find at the link below!

Fragrance Calculator:

https://www.brambleberry.com/Pages/Fragrance-Calculator.aspx

I hope this helps!

-Amanda with Bramble Berry

I’m new to soap making and its fun. 1 question. If i want to make a 3.5 1bs soap without using the size of a mold, just oils. How do i calculate the oils and water?

Any information would be helpful.

Thanks

cordially.

Hi Mahalia!

A resource that may be really helpful to you is our Lye Calculator: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

This is a tool that allows you to select what type of soap you’re making, add the amount of oils by percentage or weight, and will calculate the amount of water and lye you need, as well as giving you your yield.

If you’re wanting to make 3.5 pounds of soap, that is 56 ounces yield. According to the calculator, you will need approximately 38-39 ounces of oils. Depending on the oils you choose, the amount of water and lye will change, so make sure to run your recipe with the specific oils you are using through the calculator! 🙂

I hope that helps!

-Amanda with Bramble Berry

Hi. I’ve wanted to try making my own soap but I wonder if I can make it with only coconut oil or even virgin coconut oil. My only source for olive oil is the supermarket and it’s a bit pricey. Thanks.

Hi Ayleen!

You can make soap using only coconut oil! We actually have a great blog post about making coconut oil soap!

Coconut Oil Soap: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/defying-the-rules-of-soapmaking-100-coconut-oil-soap-with-aloe-vera-and-a-mantra-swirl/

I hope this helps you! 🙂

-Amanda with Bramble Berry

oh thanks so much for sharing!!

I have a dilemma with gel or not gel. I like my soaps creamy look. I would prefer do not gel. I have been soaping in low temp. but then I was getting my soap with soda ash. But then I get soda ash on the top of my soaps. I have read if I cover my soap and insulate and spray with alcohol I can avoid soda ash I just start to make bigger batch of soaps and I have found partial gel in my soaps. Can I let my soap without insulating at all, soaping between 85-88 F. and avoid the soda ash? How? Please Help!

Hi Vita!

Wether or not you choose to gel your soaps is totally up to you. We often gel our soaps because it not only helps prevent soda ash, but results in brighter colors. You’re correct, spraying your soap with alcohol and covering can help prevent soda ash.

My suggestion would be to slightly soap hotter by about 10 degrees. If you tend to soap at cooler temperatures, achieve a thicker trace before pouring to lessen soda ash formation.

If soda ash does appear on your soap, you can steam it off or simply clean your soap using cold water and a paper towel.

Here is a helpful post explaining how to prevent soda ash and what to do when it appears: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/explaining-and-preventing-soda-ash/

I hope this helps!

-Amanda with Bramble Berry

Hi!

when browsing through net, i happend to check that aluminum should not be used for soap making. Am using a blender which has stainless steel blade, but the shaft (the umberlla which covers the blade) is “polished aluminum”. am using this for my preparation. could you kindly guide me if its safe to use?. I made quite a few batches of soap with this, and have used them too..but happend to get bit concerned about this and thereby wanted to check with you.

Are the batches of soap which i prepared safe to use? can i continue using this blender?

Thanks

Akila

Hi Akila!

When making soap and working with lye, you want to avoid aluminum because lye reacts with aluminum. We have always found our stick blenders to work really well!

Perfect Pink Stick Blender: https://www.brambleberry.com/Perfect-Pink-Stick-Blender-P5245.aspx

I would contact the manufacturer of your blender to make sure it’s safe to use with lye. The soap that you already made is fine :).

-Amanda with Bramble Berry

Thanks for the quick reply. I shall change my blender and buy a new one which is completely stainless steel.

I do not see any discoloration in the soap batches which i had already prepared, using my old blender.

Can i use those soaps? Is it safe to use?

Thanks

Akila

Hi Akila!

I would double check your soaps using the zap-test. A zap test is sticking your tongue on the soap to test for a “zap” or lye reaction. It will be a zap like sticking your tongue on a 9 volt battery! This would mean your soap is lye heavy. I’m sure your soap isn’t lye heavy, but I would double check to make sure!

-Amanda with Bramble Berry

I have some vegetable glycerin soap that now has a white substance on it. This was a store purchased soap that someone gave me as a gift. I left it in the plastic container and now it has this white substance on it. Any idea what it is? Is the soap ok or do I have to toss it? Any help would be appreciated. Thanks.

Hi Paula,

Hmm, how strange! My first thought is that it could glycerin dew. Glycerin is a humectant, which means it draws moisture from the air and sometimes that means the moisture can pool on the surface of the soap. Check out this blog post to see pictures of what I mean:

Glycerin Dew: http://www.soapqueen.com/personal-ramblings/augh-whats-that-all-over-my-soap-2/

Does the white substance look anything like that? Let me know and I can help troubleshoot further! 🙂

-Kirsten with Bramble Berry

Thanks for the quick reply. I did a search and found that picture about the “sweat”( By the way did your brother-in-law enjoy the soap?)

My white substance looks more like a white powder. I’m wondering if there was sweating and then it dried and turned white? When I wet it, it doesn’t come off. If I rub it with my dry finger when the soap is dry, some of the white is on my finger.

I just thought you might know what it was and an easy way to get it off.

By the way, the soap was in the shape of a snow globe. There is liquid inside and a plastic figure. The liquid inside is pretty low. Maybe that was seeping through the soap?

Hi Paula,

Do you have a little more info about this, or maybe a photo? We would love to hear from you at info(at)brambleberry(dot)com. The more we know, the more we can help! Thanks Paula!

-Amanda with Bramble Berry

Hiya:

Thanks so much for your tutorial and willingness to share your knowledge! It had been a long time since I’d done CP soap, and didn’t have this problem last time, so here goes…

I used the following recipe:

Almond Oil – 3.00oz – 5.88%

Coconut Oil (76 Degrees) – 16.00oz – 31.37%

Olive Oil – 16.00oz – 31.37%

Palm Oil – 16.00oz – 31.37%

Lye – 7.550oz

Water – 16.83oz

I got to a hard trace VERY quickly. When I mixed in the fragrance oils (1 oz), the soap seems to curdle. I kept on mixing, and the soap got harder and harder, and it got very difficult to put in the molds (silicone. I ended up spooning and trying to mush it in there). While sitting in the molds, the soap has started to “melt” into a kind of crumbly goo, and it’s very hot to the touch.

I’m pretty sure I mixed the lye completely, and the oils were at around 128 degrees and the lye-water mixture was at around 134-135 when I combined them.

So where did I go wrong? And is there a way to salvage this batch if it doesn’t settle down after cooling?

Hi Isara!

We are so sorry to hear that you are having a frustrating time with your soap batch. Could you tell us more about your fragrance oil? It sounds like it might have been one that accelerated trace. The more we know about it, the more we can help troubleshoot! =)

-Becky with Bramble Berry

I’m new at soap making and so far have made one 2lb batch of simple CP soap. I would like to add some charcoal to it. What is the rule of thumb as far as amounts go for this ingredient or any other dry ingredient like ground oatmeal or dried camomile flowers for instance? Should they be added after trace? Should I separate some of the traced mixture and add the amount I need and then add it to the rest of the batch or should it be added to the oils before mixing with the lye mixture? Thanks for your help and love your videos. I can tell that you are a very patient lady.

Good morning, Mary!

We are so excited that you have started soaping and can’t wait to hear more about your soapy adventures. Typically, dried ingredients like powders and botanicals can be added in at trace. It is totally up to you how much of your botanical you add into your soap, but we suggest starting at a rate of 1 tablespoon per pound of soap (oils/butters + lye + water) to get started.

Botanicals: https://www.brambleberry.com/Herbs-and-Botanicals-C37.aspx

With the colorants (like the Activated Charcoal), you would add about 1 teaspoon per pound of soap to start out with and then experiment to find a usage rate that works for the rest for you!

If you are finding that your colorants are clumping, we suggest adding them to a bit of fixed oil (like Sweet Almond Oil) beforehand and mixing the colorant in and then adding it to your batch at trace.

For more on colorants and soap, here is a great blog post that Anne-Marie wrote:

Talk It Out Tuesday: Colorants: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/talk-it-out-tuesday-colorants/

I hope that this helps! Let us know if you have any other questions. =)

-Becky with Bramble Berry

I just made my first soap and am very happy but I noticed I added my oils to the lye and not the other way around. Will this soap be safe to use.

Hi Celia!

We are so excited that you have made your first batch and can’t wait to hear how it turns out for you. We always suggest adding your lye water to the oils for safety reasons, but your soap should be just fine. If you want to double-check after it has hardened, we suggest doing the zap test.

The zap test is where you lick the soap after it has hardened like a 9-volt battery. If it zaps, your soap is lye-heavy and you won’t be able to use it on the skin (it’ll be good for laundry soap!), if it doesn’t zap, you can use it!

I hope that this helps! If you have any more questions, let us know. We’d also love to see pictures of your soap on Bramble Berry’s Facebook page. =)

Happy Soaping!

-Becky with Bramble Berry

https://www.facebook.com/BrambleBerry

Hello,

You’ve helped me with some M&P questions and I am now confident enough to tackle CP. I’m ready to start the process but was just told by a(different) supplier that the plastic “Milky Way” molds that I used for M&P would not tolerate the higher temperatures of CP soap. Is this true? I have ordered a slab mold and can wait until it’s delivered, but I’m ready and raring to go now!

Thanks again,

Sally

Good morning, Sally!

You can actually use our milky way plastic molds for cold process, but be aware that it isn’t like melt & pour, so it might be a little more difficult to unmold and get those perfect little details. Be sure to coat the cavities of your molds with a bit of Cylocmethicone to help them pop right out. I hope that this helps! =)

-Becky with Bramble Berry

Cyclomethicone: https://www.brambleberry.com/Cyclomethicone-P4560.aspx

Thank you, once again. I really appreciate having a trusted source to go to for questions.

Sally

Good morning, Sally!

We can’t wait to see how your soaps turn out, be sure to share any soapy pictures that you may get on Bramble Berry’s Facebook page. =)

Happy Soaping!

-Becky with Bramble Berry

https://www.facebook.com/BrambleBerry

Is there a good rule of thumb to estimate how much your finished soap will weigh?

I mean after it has finished curing.

Hi Aimee!

To find out how much your finished soap will weigh, add your lye + water + oils/butters and you will get the final weight. You will probably lose a bit of weight after it has cured, but there is not exact formula to figure out how much. I would suggest taking a look at the recipe you are working with and weighing it once it has hardened versus once it has cured. You will then know how much that particular recipe will weigh once cured. I hope this helps! =)

-Becky with Bramble Berry

I have read anywhere from 20-25%, but it does seem that could vary greatly depending on the specific ingredients used, and possibly even where you live. I think the weighing before and after curing method will be my best bet.

Thanks! Love the blog!

Hello, I have question about colorants. I am trying out oxides to color my soap. I used a red and I guess I used too much because the suds are red. Do I have to trash the batch? What can be negative issues for soap with too much colorants and colored suds. I imagine it would be fun for kids to have colored suds, but will it stain things(skin, tub, sink, clothes ect?) Also, so this does not happen again, how do I know how much to use in he future? I premixed it 1/4 tsp to 1 oz oil like I read somewhere. Any help would be wonderful.

Good morning, Christine!

It sounds like you might have over-colored your soap a bit — but it isn’t harmful. You are just going to have colored suds that may get on you and the washcloth. If that is too much colorant for you, you can always rebatch your soap and not add any extra colorants. Here are some links about rebatching that I’ve found to be super helpful:

Rebatch – Double Boiler Method: http://www.soapqueen.com/bath-and-body-tutorials/rebatch-double-boiler-method-2/

Soap Queen TV Presents: How to Make Rebatch Soap: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

The amount of colorant you use actually depends on what kind of soap you are making and the colorant you are using. For an easy guide reference, here is a post that Anne-Marie wrote a few years ago that I use every time I am soaping.

Talk It Out Tuesday: Colorant: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/talk-it-out-tuesday-colorants/

I hope that this helps! =)

-Becky with Bramble Berry

Thank you so much for the quick response! I will check those out!

I’m wondering what I can use to replace the coconut oil in the soap. My friend who is helping me with this is severely allergic, so I’m just wondering what would make for a nice alternative?

Thanks!

Good morning, Grace!

If you don’t want to use Coconut Oil in your recipes due to an allergy, and still want a nice hard bar of soap, here are some amounts that can work for you:

30% Palm Oil

https://www.brambleberry.com/Palm-Oil-P3210.aspx

40% Olive Oil

https://www.brambleberry.com/Olive-Oil-Pure-P5246.aspx

15% Rice Bran Oil

https://www.brambleberry.com/Rice-Bran-Oil-P4971.aspx

10% Sweet Almond Oil

https://www.brambleberry.com/Sweet-Almond-Oil-P3205.aspx

5% Palm Kernel Flakes

https://www.brambleberry.com/Palm-Kernel-Flakes-P3446.aspx

I hope that this helps! Let us know if you have any other questions. =)

-Becky with Bramble Berry

Hi,

as You mentioned that soap may tend to “cling” to silicone mold a bit longer, I wonder is it possible that soap also cling to silicone mold if I leave it there few days longer (too long)? Once I left it in silicone mold for 2 days and it was impossible to get it out in one piece. Did I fail patience test? It seems to me that too short and too long curing in silicone mold is bad.

Thank You in advance!

Hi Lili!

You should be able to pop your soaps right out of the silicone molds without them breaking. Sometimes, we have found that you even have to leave them in there up to a week after you’ve made the soaps for them to be fully dry. Next time you use your silicone mold, try leaving it in there a couple more days to see if that helps out! =)

-Becky with Bramble Berry

Hi Becky,

thank You very much!

Just to let You know – I have put soaps together with silicone molds for a few hours in freezer and the poped out perfectly :))

Hi,

In reference to one of your earlier comments, I am using a large slab mould with my CP recipe and I want to ensure I force gelling all the way through. Previously I got a partial gel. This is a large mould (8lb)and I have used a heated blanket and still only got about a 75% gel. I left the heated blanket switched on all night on a low setting to help -but still a partial gel. Any tips?

Thanks

Hi O!

The best way that we have found for our batches to go through a full gel is to make sure they are on a heating blanket as well as being fully insulated with a towel. To do this, cover the top of your mold with a piece of cardboard and wrap the entire mold in a towel to insulate it. This should help to force your soap to go through a full gel! I hope this helps. =)

Happy Soaping!

-Becky with Bramble Berry

After a lot of experimenting with CP and CPOP, I’ve decided I like to let the soap go through gel phase. I don’t want to do CPOP any longer, and I don’t like soaping at room temperature. When I soap at 125-130degrees, I’ve never had a problem getting a thorough gel by insulating CP. My question, and it may be a silly one, is what’s the lowest temp that will still go through gel phase? I’ve tried soaping and room temp, and didn’t like it too much.

Thanks

Hi Denise!

It is always so much fun to experiment with soap and to see what works the best for you, we can’t wait to hear more about your soapy creations. That isn’t a silly question at all, we are here to help you answer it. I am actually going to do some soapy research on your question and get back to you on it! I hope that is okay. =)

-Becky with Bramble Berry

P.S. I was able to do a bit of research on the question that you asked and I have an answer. You can soap as low as you would like, but 80 degrees Fahrenheit is as low as we would recommend going as Coconut Oil (which is in most recipes), hardens at 76 F.

If you are soaping at lower temperatures and do want to go through gel phase, you will need something to help ‘jump-start’ the process. We suggest insulating with a towel and applying heat through a heating blanket. But, if you are soaping at low temperatures, even putting a heating blanket on it will not guarantee gel phase.

We suggest soaping around 120-130, insulating and even adding a heating blanket on low if you want your cold process batches to go through gel phase.

I hope this helps! =)

I’m interested in getting a full fask mask to use while making cold-process soap? What ones do they use at Brambleberry?

Thanks!

Hi R!

At this time, we don’t sell any full face masks and actually soap in a very open lab (for full air flow). If you are interested in getting a face mask, I would check your local hardware store to see what they have available. =)

-Becky with Bramble Berry

Hi I was wondering what steps are taken to prep all of your tools to keep them sanitary to be used. Do you use alcohol or a bleach solution to sanitize everything? How far in advance would you take these steps. I have my cp kit ready to go but want to make sure to have the cleanest and most sanitary tools possible. I have ocd and if everything isn’t in order I might just freak out, lol, not really but I am a stickler for keeping everything in it’s place and being comppletely prepared. Thanks in advance for your assistance 🙂

Hi Dawn!

If you want to make sure that all your tools are clean and good to use in your soaping, we would suggest sanitizing them in a 5% bleach water solution. After you are done using them, be sure to clean them well with a oil-cutting dish soap like dawn. I hope this helps! 🙂

-Becky with Bramble Berry

Thank you 🙂 I’ve been so busy getting ready for our 3rd baby girls arrival that I haven’t had a chance yet to get my soap made before we have to move. It’s my first batch and I’m super excited!! I believe I have watched Anne Marie’s videos a million times now 🙂 So excited about this 🙂 Will post pictures on the fb page when I get them made 🙂 Thank you SO much for all of your help, you always are so quick and sweet and I LOVE that 🙂

Just made my first cold process soap! What does it mean if your soap thickens after you’ve blended and added fragrance oil? Mine seemed to almost solidify, I was able to pour it as one sort of gelatinous glop. Definitely not the pudding like trace I thought I had reached! Thanks for any advice.

Hi Emily!

Congrats on your very first cold process soap, isn’t it so much fun!! =) Sometimes certain fragrance oils can actually accelerate trace so that your soap get super thick. I’d love to help you troubleshoot what happened, which scent did you use in your batch?

-Becky with Bramble Berry

I used ocean rain, about 1.7 ounces for a 2 pound batch. I used the soap recipe that comes with your beginners cold process kit. I took it out of the mold and cut the soap down yesterday, it seems fine. I wondered about the fragrance oil too, as it seemed at the appropriate trace stage right before I added the fragrance.

Thanks for your help, looking forward to my next batch!

Hi Emily!

We’ve never had problems with Ocean Rain accelerating trace in our soaps and it does have that lovely sticking power that makes it smell absolutely fabulous. Did you add any extra colorants or additives? If you have any pictures of your first cold process soap, we’d love for you to share pictures of it with us on Bramble Berry’s Facebook page. =)

https://www.facebook.com/BrambleBerry

-Becky with Bramble Berry

The smell is fabulous! I did not add any other colorants or additives, just the fragrance at the end. Is it possible to over mix? Maybe I stick blended for too long prior to adding fragrance? I didn’t take any photos from this batch, but next time i will and add them to Facebook. Despite the rapid thickening from this batch, all seems good. And my basement smells lovely from the ocean rain fragrance 🙂

Hi Emily!

You can over-mix your soap batter if you go past heavy trace. How long did you stick blend it for before you added your fragrance in? I am so glad to hear that your soap turned out so well! Ocean Rain is actually one of my favorite “clean” type fragrance oils to use and I’m glad you are liking it as much as I do. =)

Happy Soaping!

-Becky with Bramble Berry

I don’t remember exactly how long, maybe somewhere between 1-2 minutes. It didn’t seem that long! I will try to shorten that some next time and see if that makes a difference. Thanks for your help!

Good afternoon, Emily!

I would try pulsing your stick blender instead of a full-on blend to see if that would help for your 1-2 minutes. I would also suggest checking out this blog post that takes about trace and emulsion, there are some great tips in it!

http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/hscg-conference-guest-post-peacock-swirl-class/

-Becky with Bramble Berry

Thanks! I made a batch today and it worked out much better! Pulsing helped, and after adding fragrance it seemed to reach an ideal consistency. Looking forward to checking it out tomorrow! Thanks for your help!

Emily

Hi Emily!

We are so happy to hear that it worked out better for you on this second batch. Be sure to keep us updated on how the final result turns out. =)

-Becky with Bramble Berry

Hello. I plan on making cp soap and I will be using silicone loaf molds because that’s what I have on hand. I have read in books that molds need to be insulated with towels or blankets. Do I need to insulate my silicone molds? Also, later when I’m able to buy or make wooden molds, do I need to insulate them also. Thank you for your response.

Hi Barbara!

We are so excited that you have started soaping and can’t wait to hear more about your first cold process batch. Insulating soap after molding will promote gel phase in your batch. Gel phase is a temperature phase during the soapmaking process and can actually give your soap a shinier, slightly translucent look. It’s totally up to you if you gel, but if you want to make sure that the gel phase extends throughout your entire batch, you will want to insulate your soap! I hope this helps! =)

-Becky with Bramble Berry

Thanks for responding. I’ll take your advice and I will send you a picture!

what is lye? from where i can get that?

Good morning!

Lye is an ingredient that makes soap, well, soap! Without it, you would just have a bunch of unsaponified oils and butters that wouldn’t make a soap. Lye is what transforms all of those skin-loving ingredients into soap through the saponification process. You can actually purchase it on Bramble Berry’s website here:

https://www.brambleberry.com/Sodium-Hydroxide-Lye-2-lbs-P3037.aspx

You can also check out this great intro series into Cold Process Soapmaking on Soap Queen TV:

http://www.youtube.com/playlist?list=PLAADF6209996265D2

If you have any other questions, let us know so we can help you out! =)

-Becky with Bramble Berry

With all the information out there about the effects of palm oil, I’m wondering why most soap making recipes still contain this ingredient? There is no such thing as sustainable palm oil as is claimed by suppliers and it’s not traceable and it won’t be until at least 2020. Is it because they are old recipes and no one wants to take the time to recalulate them using a different oil? It seems so unethical to keep promoting this product when there has to be other options.

Hi Karen!

Thank you so much for stopping by! We always appreciate it when our customers take the time to let us know how they feel about these important issues. If choose not to use Palm Oil in your soaps, it is totally up to you and there are many great soapmaking alternatives to using Palm Oil in your soaps. Anne-Marie actually wrote a great post about this very issue, and I find myself referring to it often. Here is a link: http://www.soapqueen.com/business/on-palm-oil/

You can also check out these Palm-Free recipes from the blog:

Palm Free Vertical Twist Tutorial: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/palm-free-vertical-twist-tutorial/

A Palm Free In-The-Pot Swirl: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/a-palm-free-in-the-pot-swirl

Sea Clay Avocado Facial Bar: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/sea-clay-avocado-facial-bar/

Baby Soap: Buttermilk Bastille Baby Bar: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/baby-soap-buttermilk-bastille-baby-bar/

Easy Cold Process Soap Rocks – Palm Free!: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/easy-cold-process-soap-rocks-palm-free/

Thank you again and I’ll ask Anne-Marie to see if she’ll be able to create a few more palm-free recipes for our customers. =)

-Becky

I am still super confused about the percentages. What is this a percentage of?? A percentage of the total weight of oils? How do I know the total weight of oil? HELP!! And why is it done in percentages, anyway? Why not just weight or volume?

Hi Emily,

I’d be happy to help you out! We give the percentages so this recipe can be adapted for any size mold — think of them as ratios!

So let’s say you are making soap in our 5 lb. wood log mold. You would go to our lye calculator and under where it asks “Are You Measuring in Grams or Oz (or Just Percentage) of Oils?” choose “percentage.” Now you can enter in all your percentages.

Then it will ask you how much the oils will weigh in the finished product. Generally our rule of thumb is the oils will weigh 30% less than the total yield.

So if the total yield of the soap is 80 oz. (remember we’re using a 5 lb mold, and 5 lbs is roughly 80 oz.), then 30% less of that would be about 56 oz. Here is the math I did so you know exactly where these numbers are coming from — (80 x .3 = 24) and (80-24 = 56).

I chose a 5% superfat. When I click calculate, here is what I get:

Coconut Oil (76 Degrees)– 16.80oz (30.00%)

Olive Oil — 16.80oz (30.00%)

Palm Oil — 16.80oz (30.00%)

Sweet Almond Oil — 5.60oz (10.00%)

5% Lye (Sodium Hydroxide) Amount — 7.991oz

Ounces of liquid recommended — 18.48oz

Yields — 82.47oz

I hope that helps! I completely understand how confusing this can be, so don’t hestiate to ask more questions! 🙂

Lye Calculator: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

5 lb. Wood Log Mold: https://www.brambleberry.com/5-Lb-Wood-Log-Mold-with-velcro-straps-P3612.aspx

-Kirsten with Bramble Berry

So my question is – how necessary is all of this measurement precison? Would my soap making be greatly improved by purchasing a digital scale? Personally, I would love a recipe as follows: a cup of this, a tablespoon of that, and a pinch of the other thing. Wouldn’t that be great?

The precision measurement is important to soaping, because you need a specific amount of lye depending on the weight of your oils. If your oil weight is off, you could end up with too little or too much lye in your soap and it would be lye heavy and not usable. We always like to go by weight, because it is easily repeatable and any of our readers will be able to make the same exact soap by following our recipes. I totally get what you mean about having a more simpler way of measuring the recipe, but in the case of lye, you really want to make sure your measurements are spot on! =)

-Becky with Bramble Berry

Hello fellow soap makers! I’ve been making cold process soap for many years and ocassionally enjoy “getting back to basics” by reading tutorials. This is a good one. One of the things that I’ve noticed changing over the years is the insistance on precise measurements. When I learned to make soap no one I knew was using digital scales – measurements and temperatures were not precise. I have experimented with many combinations of oils, temperatures, additives and scents; most of my soaps have been great for gifting or bartering and some have been suitable only for home use. A few have been somewhat disasterous, but at the end of the day I always made … soap. It might not always be beautiful but it cleans you in the shower. Now I see recipes that call for very precise measurements, like 2.31 ounces of lye. Really? I don’t own a digital scale – I still use an old kitchen scale I’ve for 20 years.

Hi Jillian!

Thank you so much for stopping by, we appreciate your comment. We have found that having precise measurements for your soaping really helps accuracy in your recipes, and makes sure that your soaps aren’t lye heavy. We do this because many of our customers are selling these products, and we want to make sure these recipes are nice and mild on the skin and won’t be harsh for anyone with sensitive skin. It is also important to have precise measurements because volume measurements are different than weight measurements because each oil has a different specific gravity. This means that 1 ounce of Coconut Oil by volume is actually not going to weigh the same as 1 ounce of Hazelnut Oil by volume. One is actually more dense than the other and the actual weights will be different. Going by weight also helps with predictably in results. I hope that this helps to explain it a little more and it’s great to hear that your recipes are working for you and aren’t lye heavy. =)

-Becky

Do you think that plastic is a safe utensil to work with lye? I would think that dangerous gases from the plastic would be brought out and eventually end up in our soap.

jean

If the plastic container is heat safe, it should not react with the lye or heat up to release gases. I’ve never found that to be the case. But when in doubt, you can always go with Stainless Steel or heat safe, tempered glass. =)

Thank you for your very informative site. I would like to make soap without palm oil as I think it is an industry I do not want to support, but most recipes seem to contain it. Do you have a suggestion for a substitute? Thank you in advance.

Hi Lori!

We totally understand not wanting to use Palm Oil in your recipes and that is why we use Palm Oil from a sustainable source. You can read more about it in this blog post that Anne-Marie wrote:

On Palm Oil: http://www.soapqueen.com/business/on-palm-oil/

If you don’t want to use Palm Oil in your recipes, you can always use something like Rice Bran Oil as a substitution or add a bit of Sodium Lactate to help harden up your bars. If you do change the recipe, you will want to make sure you run your recipe through the lye calculator again so that your oils saponify correctly.

Lye Calculator: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

Sodium Lactate: https://www.brambleberry.com/Sodium-Lactate-P5127.aspx

Rice Bran Oil: https://www.brambleberry.com/Rice-Bran-Oil-P4971.aspx

And here are a few palm-free recipes from the blog that you can play around with:

Sea Clay Avocado Facial Bar: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/sea-clay-avocado-facial-bar/

Palm Free Vertical Twist Tutorial: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/palm-free-vertical-twist-tutorial/

A Palm Free In-The-Pot Swirl: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/a-palm-free-in-the-pot-swirl/

Easy Cold Process Soap Rocks – Palm Free!: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/easy-cold-process-soap-rocks-palm-free/

I hope this helps! =)

-Becky with Bramble Berry

Hi – I’m sort of in the same boat, I do not want to use Palm oil, soybean oil or animal fat. Very hard to find recipes that do not have palm oil so thank you for posting.

I recently bought some soap and bath bombs from another soaper and I discovered I really do not like the smell of fragrance oil at all, but I love LUSH so I’m wondering if they use EO instead of fragrance oil? I spent a small fortune and I hate all of it, makes it smell cheap like a scented waxy crayon or something. I’m wondering if all fragrance oil smells yucky or maybe she uses a poor brand or something? It’s an expensive lesson, but at least I didn’t go ordering a bunch of fragrance I wouldn’t want in my own products, maybe EO is the better way to go for me.

Thanks for all your advice – Karen 🙂

Hi Karen!

If you aren’t using Palm Oil in your soap, here are some great Palm Oil, Soybean Oil and Animal Fat-free cold process recipe that you can try out.

Sunset Over the Water by Lovin’ Soap: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/sunset-over-the-water-by-lovin-soap/

A Palm Free In-The-Pot Swirl: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/a-palm-free-in-the-pot-swirl/

Palm Free Vertical Twist Tutorial: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/palm-free-vertical-twist-tutorial/

Easy Cold Process Soap Rocks: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/easy-cold-process-soap-rocks-palm-free/

Buttermilk Bastille Baby Bar: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/baby-soap-buttermilk-bastille-baby-bar/

Sea Clay Avocado Facial Bar: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/sea-clay-avocado-facial-bar/

I hope these will be able to give you some extra soapy inspiration. With fragrance and essential oils, the vendors you are getting your bath & body products from probably use both. If you have a favorite type of scent I can suggest a few fragrance or essential oils to try out. You can even request a ‘sniffy sample’ to see which of Bramble Berry’s scents you would like. For more information on sniffy samples, you can check this link out:

https://www.brambleberry.com/Fragrance-Oil-Information-W33.aspx

I’m a fan of both essential and fragrance oils, but it really depends on the scent for me. I hope this helps! Let me know if you have any other questions. =)

-Becky with Bramble Berry

ben sizden içine konulan kimyasal maddeleri sıra ile yazarsanız sevinirim ben TÜRKİYE den yazıyorum size veya sabun yapmada kullanılan maddeleri sizden temin edebilirmiyim

Good morning, Mehmet!

If you are looking for the ingredients in our Melt and Pour bases, you can find them on each individual product page.

For example, the ingredients in the Clear Melt & Pour Soap Base are:

Coconut Oil, Palm Oil, Safflower Oil, Glycerin (kosher, of vegetable origin), Purified Water, Sodium Hydroxide (saponifying agent), Sorbitol (moisturizer), Sorbitan oleate (emulsifier), Soy bean protein (conditioner)

Clear Melt And Pour Soap Base: https://www.brambleberry.com/Clear-Melt-And-Pour-Soap-Base-P3189.aspx

I hope this helps! Let me know if you have any other questions. =)

-Becky with Bramble Berry

Günaydın, Mehmet!

Bizim Erimesi ve dökün üsleri maddeler arıyorsanız, size her ürün sayfasında bulabilirsiniz.

Örneğin, Clear bölgesindeki maddeler eritin ve Sabun Bankası edilir dökün:

Hindistan Cevizi Yağı, Palm Yağı, Aspir Yağı, Gliserin (kosher, bitkisel kökenli), Saf Su, Sodyum hidroksit (ajan saponifying), Sorbitol (nemlendirici), Sorbitan oleat (emülgatör), Soya fasulyesi proteini (kremi)

Melt Temizle Ve Pour Sabun Bankası: https://www.brambleberry.com/Clear-Melt-And-Pour-Soap-Base-P3189.aspx

Bu yardımcı olur umarım! Başka bir sorunuz varsa bana bildirin. =)

Bramble Berry-Becky

i used 1 and half ounces of spearmint…i didnt measure the coloring ,i just kinda poured it in there…lol…and thank you for the link for colorant as i was trying to figure out something else to use…i am going to check it out now..thanks K

God morning, Karen!

We always suggest making sure to measure your colorant in colorant as too much could actually cause your soap to lather colored bubbles. For more information on our colorant usage rates and types of colorants you can check out this blog post:

Talk It Out Tuesday: Colorants: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/talk-it-out-tuesday-colorants.

If you are using our fragrance or essential oils, you can always use the Fragrance Calculator to figure out how much to use in your soap batch.

Fragrance Calculator:https://www.brambleberry.com/Pages/Fragrance-Calculator.aspx

I’m thinking it might have been the colorants that you used that turned your soap that caramel color. But, if you didn’t like how it turned out, you can always rebatch your soap. Here is a video tutorial that Anne-Marie has made on just how to do that:

How to Make Rebatch Soap: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

I hope this helps! Let me know if you have any other questions. =)

-Becky with Bramble Berry

I just finished my very first batch of CP soap…i took out one cup after trace and fragrance in which to add green soap coloring…my problem it came out looking like carmal …what did i do wrong…the coloring i got from ebay and it said it was for soap..my oil recipe was this

olive–12oz

canola—8oz

grapeseed–8oz

coconut–8oz

castor –4oz

maybe i added to much

How much colorant and fragrance did you add to your batch? 🙂

-Becky with Bramble Berry

Good morning, Karen!

Your recipe looks great and sounds like a super lovely bar of soap. What fragrance did you use? Sometimes your soap can come out dark if you use a fragrance that discolors.

If you are looking for a good quality source of soapy colorants, here is sample pack (that has been tried, true and tested in CP soap) that could totally work for you:

Pigment Sampler Pack: https://www.brambleberry.com/Pigment-Sampler-Pack-1-sampler-pack-P3449.aspx

I hope this helps! 🙂

-Becky with Bramble Berry

I have never made soap and want to start making CP process for my family as well as try to sell at a farmers market this summer. I have found the ingredients I want to use but how do I know how much of each. I haven’t found a reciepe that uses all of these, Olive Oil,Soy oil, Palm Oil, Coconut oil, Palm Kernel, Castor oil,Shea butter, and oatmeal. Oh and Lye of coarse.

Hope you can help.

Sandy…if you have a smartphone, you can download a handy lye calculator. Brambleberry has one on their website.

Here is our free lye calculator that you can put these percentages into:

https://www.brambleberry.com/Pages/Lye-Calculator.aspx

Lather, Hard

25% Palm

25% Coconut

10% Palm Kernel

32% Olive

5% Shea

3% Castor

Moisturizing

20% Palm

15% Coconut

5% Palm Kernel

47% Olive

10% Shea

3% Castor

I’d go with a 5% superfat on the Lather, 7% on the Moisture.

Oatmeal – I’d grind it up and add it in at thin trace but not very much – maybe 1 tsp per pound of soap, total.

I have been making M&P soap for about 2 years now. I have been wanting to make CP soap for some time, but have been kind of overwhelmed at the idea of it. I have done my research (thanks to your resources!!) and am ready to go. Well, I have gathered all the tools of the trade and am almost sitting here looking at them. My head is swimming with information. I think I am just going to have to jump in with both feet. I will let you know how it goes!